Glass machining and optics

Huygens Optics is a one man operation and is run by Jeroen Vleggaar. In my workshop I have all the necessary equipment to make parts from glass and ceramics, such as

NBK-7, S-BLS7, borosilicate glass, quartz, Zerodur, CLEARCERAM and Ceran. I can also machine materials used in infrared applications, like Germanium.

Basically all materials from suppliers such as Schott, Ohara and Heraeus can be ordered and processed into parts.

A limited supply of borosilicate glass and Zerodur is in stock.

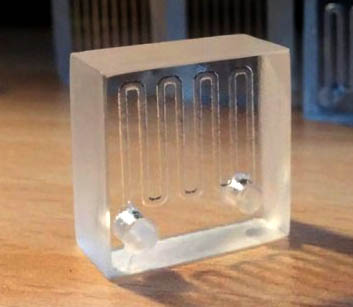

Parts can range in complexity from simple to complex (with internal structures). Existing parts, such as optical filters, can be cut to the required dimensions.

Parts used in mechanical applications can be modified in size, flatness, or parallelism.

The workshop contains all standard diamond tooling to do the following machining operations on glass and ceramics: drilling, sawing, milling, radius milling (up to 130mm), and rough/fine grinding.

Maximum object size for most operations is approximately 300mm. The standard dimensional accuracy is 0.2mm

Fine grinding can lower the RMS roughness of surfaces to around 0.3μm.

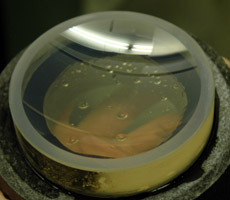

The roughness can be further lowered by using pitch polishing.

With this method, the surface roughness can be lowered to a few nanometers RMS and a peak to valey (P-V) flatness of 10 nanometers over distances of 250mm.

Pitch polishing can also be used to produce spherical- and aspherial optical surfaces.

With most common optical surfaces, an interferometric test report can be supplied.

Applications of glass and ceramics

As material classes, glass and ceramics have several unique properties such as:

- Low or zero coefficient of thermal expansion (CTE)

- High mechanical stiffness (high Youngs modulus)

- Good electrical isolation (high-voltage applications)

- low outgassing and hermetic (high-vacuum applications)

- Resistant to high temperatures

- Chemically inert to solvents

- Resistant to high-energy radiation

- Wear resistant

The combination of the above properties make them suitable for very demanding applications. Glass and ceramic parts can be used under conditions where plastics and metals do no longer perform well.

Which specific material is most suitable for an application is dependent on the customer demands.

Optics en characterisation

Huygens Optics has experience in the design of optical systems using simulation software.

With this software, the performance and tolerances of an optical system can be calculated and optimized before it is manufactured

Prototypes can be based on existing lenses from commercial suppliers, as well as on custom manufactured optical components.

Huygens Optics can also manufacture and test prototypes.

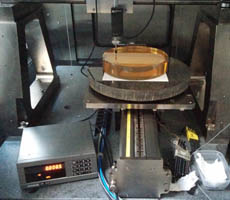

For making custom components, a CNC radius milling machine, a polishing machine, an optical centering machine as well as te nescessary tooling and materials are available.

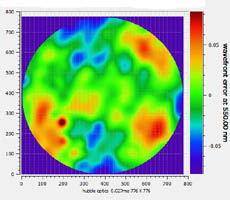

Flat optics can be measured to a diameter of up to 240mm and and accuracy of ~ 30 nanometers.

There is also a setup for measuring other types of reflective and transmissive optical elements.

For more information on any of the above please contact me.

Back to the list of all services

|

Polishing of sferical en asferical surfaces

Complex internal- and external structures

Production of flat optics

Design of optical systems

3D-characterization of objects

Measurement of optical wavefront

|